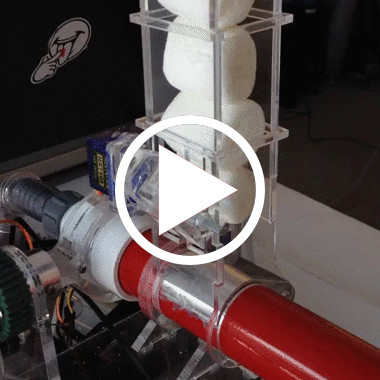

Reloading Mechanism

We can completely automatedly fire six marshmallows in less than ten seconds.

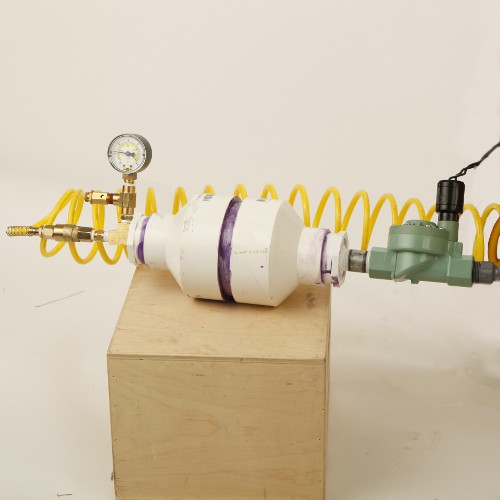

Pneumatic System

This puts our marshmallows under pressure.

Pan/Tilt Actuation

We have about 200 degrees of horizontal motion and 60 degrees in the vertical axis.

Our Reloading Mechanism.It uses two nano servos and a variety of custom-fabricated components.

Our reloading mechanism can hold around six marshmallows.

The marshmallows are held in an acrylic magazine. One servo, an HXT900 microservo, is used to cue marshmallows for loading and prevent multiple marshmallows from falling into the barrel. The barrel is sealed by a billet aluminium hatch, articulated by a metal-gear, digital microservo. The reloading mechanism takes approximately one second to load a new marshmallow, making it faster than the regulator recharges the pneumatic system.

Our pneumatic system. It contains some air.

Our pneumatic system provides the impulse necessary to shoot our marshmallows.

The first part of the pneumatic system is the compressor, capable of producing up to 135 PSI. We bought a used compressor that included a regulator and two (sadly quite inaccurate) gauges. The regulated output of the compressor is connected to our pressure reservoir that has its own more accurate pressure gauge as well as a safety release valve, set at 30 PSI. Our PVC reservoir has approximately three times the volume of the barrel of the launcher, which is plenty of air to launch the marshmallow. The pressure is released into the barrel by a standard solenoid-powered sprinkler valve, connected via relay with our microcontroller. When the solenoid is triggered, the air in the reservoir is released through a length of clear tubing to the barrel. After the valve closes, it takes a few seconds for the pressure in the reservoir to recover, based on the setting of the regulator.

Our pan and tilt system. It pans and tilts.

We could have called it azimuth and elevation, but then the project would seem even more like we just made an artillery piece.

Our two-axis actuation is, again, powered with servos. The panning uses a continuous rotation standard-sized servo coupled to an angle-feedback potentiometer. To tilt the barrel, we used a high-torque metal-gear analog servo geared down for 60 degrees of range. The servo is coupled to the barrel through two machined aluminium blocks, one of which is supported with a bearing.